High Performanced and Competitive Product: Tecotron® PPS

eurotec® continues to serve to stringent sectors with its high-performance plastics portfolio and its long-standing of application experience.

eurotec® continues to design its portfolio of high-performance plastic products, which are easy to process and have sustainable quality, to meet the competitive product expectations of the industry.

Tecodur® PBT FR Series for E&E Applications

eurotec® continues to adapt its long-standing experience in flame-retardant products to meet the changing demands of the industry.

For plastics to be used safely in critical applications, they must exhibit appropriate performance according to international test standards when in contact with flame. eurotec® continues to design its flame-retardant product portfolio, which is easy to process and has sustainable quality, to meet the competitive product expectations of the industry.

We Have Completed the Last Fair of the Year

We have completed our participation at Plast Eurasia Istanbul Fair together with our distributor, Safic Alcan. We would like to sincerely thank all our team members who supported the fair held at Tüyap.

During the fair, we had the opportunity to meet with our valued friends and business partners with whom we have had business relations for many years.

We strengthened our business relationships with our partners and also met new people and discussed new business opportunities.

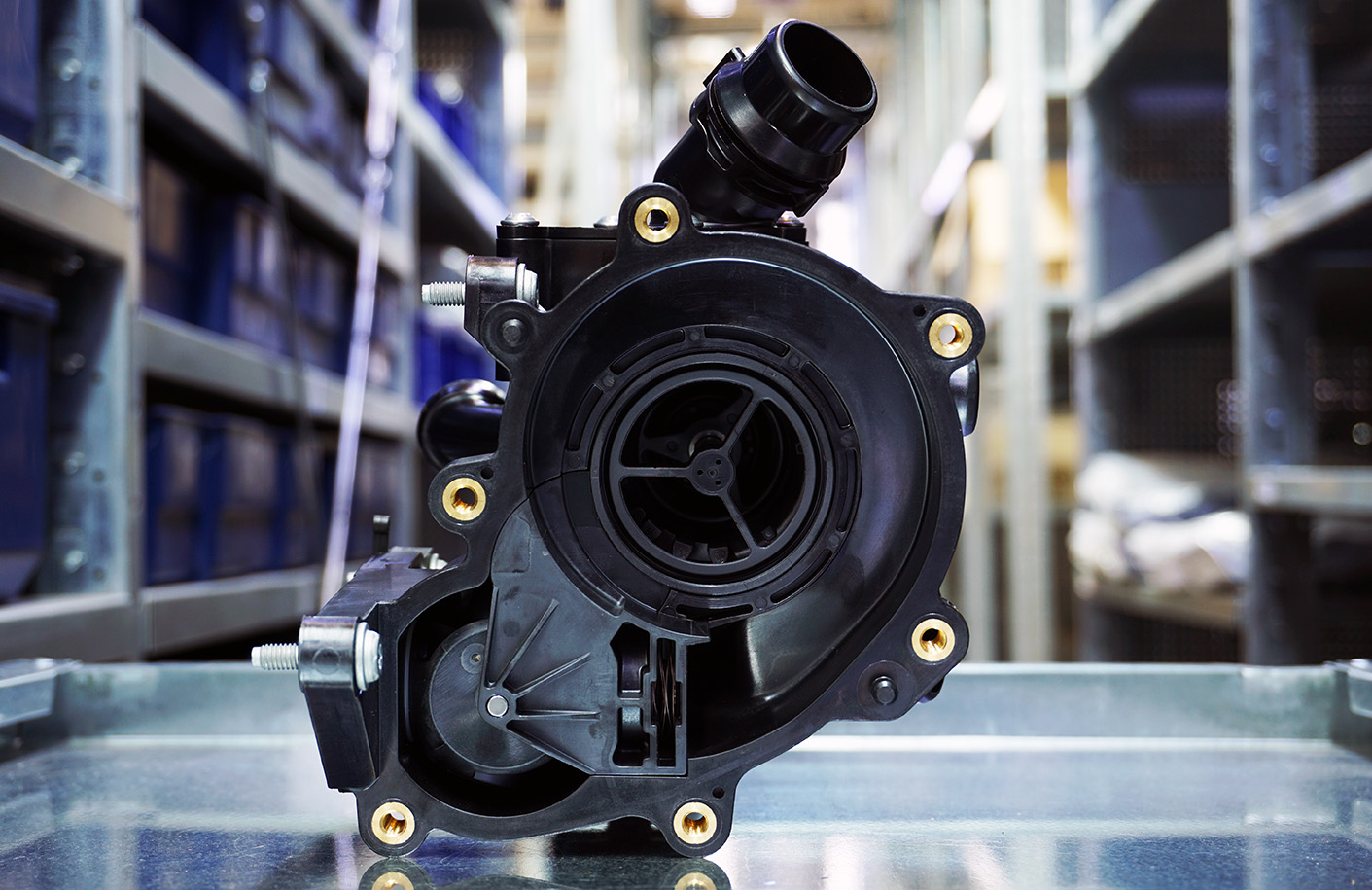

Tecomid® HT NT40 GR35 BK009 HS is approved for use in filter housing applications in the industrial life sector. (PPA, 35% glass fiber reinforced, heat stabilized, black)

- Good surface quality.

- It has high mechanical strength and high impact resistance.

Tecomid® ECO NB43 GR30 BK005 HS M65I is approved for use in composite chassis applications in the automotive industry. (r-PA6, 30% glass fiber reinforced, heat stabilized, black)

- Low Carbon Footprint

- 65% PIR content

- Good surface quality and high mechanical strength.

Tecomid® NB40 GR30 BK012 XA6X (PA6, halogen free flame retardant, heat stabilized, black) is approved for use in cable tray applications within the rail systems industry.

- High mechanical strength.

- Good surface quality.

- EN 45545 HL3 R22/R23

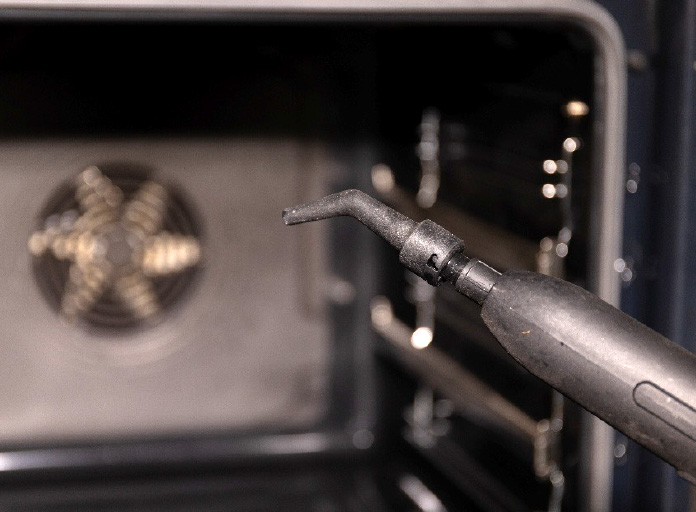

Tecopeek® PK40 GR30 BK014 is approved for use in cooker applications in the daily life sector. (PEEK, 30% glass fiber reinforced, black)

- Excellent temperature resistance.

- It has excellent mechanical strength and impact resistance.

eurotec® Achieves UL Certification for Halogen-Free Flame Retardant PA66 Product

eurotec® 's 25% glass fiber reinforced PA66 halogen-free flame retardant product has been granted UL approval in the V0 flame resistance category for thicknesses of 0.75, 1.6, and 3.2 mm.

UL finalized its research on the product code Tecomid® NA40 GR25 NL XA60 and confirmed its compliance with flame resistance requirements. Tecomid® NA40 GR25 NL XA60 has been developed to meet the electrical and mechanical properties expected in critical applications, in addition to its V0 flame resistance. It is suitable for safe use in electrical and electronic applications in the automotive, white goods, small household appliances, lighting, and construction sectors.

Meetings Continue

The Light-G-Comp Project completed its 9-month review in Abu Dhabi, hosted by Khalifa University.

Partners from Türkiye and the UAE are developing sustainable, high-performance composite solutions for aerospace and automotive applications.

As eurotec®, we are happy to share our expertise and be part of this valuable project.

eurotec® Continues to Create Reliable Solutions for Critical Sectors with Its Certified Products

As eurotec®, we prioritize certification by having our tailor-made solutions tested in accredited laboratories:

- WRAS and KTW certified products for applications in contact with drinking water

- UL yellow card certifications verify the performance of our products

- Recycled content products certified under UL 2809

- Products certified under EN-45545 standard for use in railway vehicles

You can find our our all certificated products ON OUR WEBSITE.